notes:

-

discussed that most of the work in this class is subtractive (take a bigger piece of material than the output, and subtract pieces from it).

-

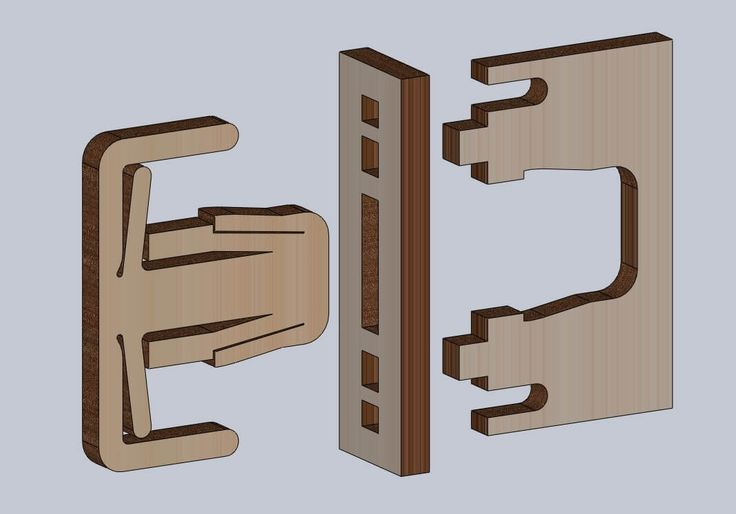

saw compliant mechanisms, (one piece, one positive, one negative).

-

all laser cut machines here use inches. cms is base 10, inches is base 12.

- all materials have a sds (safety data sheet).

- introduced us to the laser cutter.

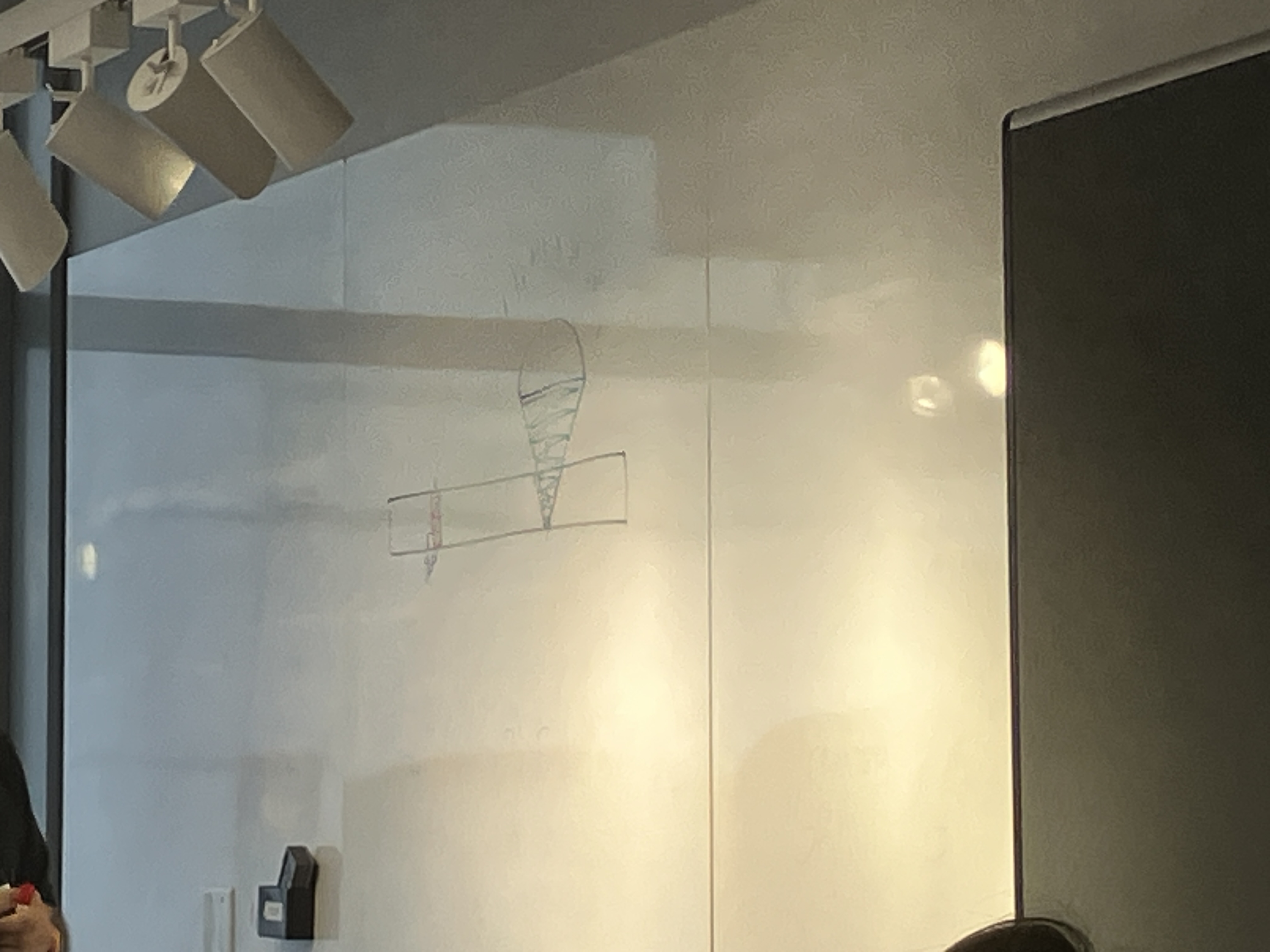

- laser is a beam of light, which is sharp-angled at the bottom (converges at a point).

- introduced kerf bending: since the beam is a triangle, if you flip the material over, the material bends.

laser printer stuff:

- stroke has to be 0.01, uniform, basic.

- the printer talks to the computer with the colour:

- no fill with stroke (one of the available colours on the template) means cut-through.

- black with no stroke will remove surface of material.

- gradient varies the power the laser uses (giving you cut-gradation).

- other settings to do on the printer itself:

- autofocus: plunger? don’t know what that is.

- split by colour, cut by vector.

- inside to outside cuts.

assignment ask:

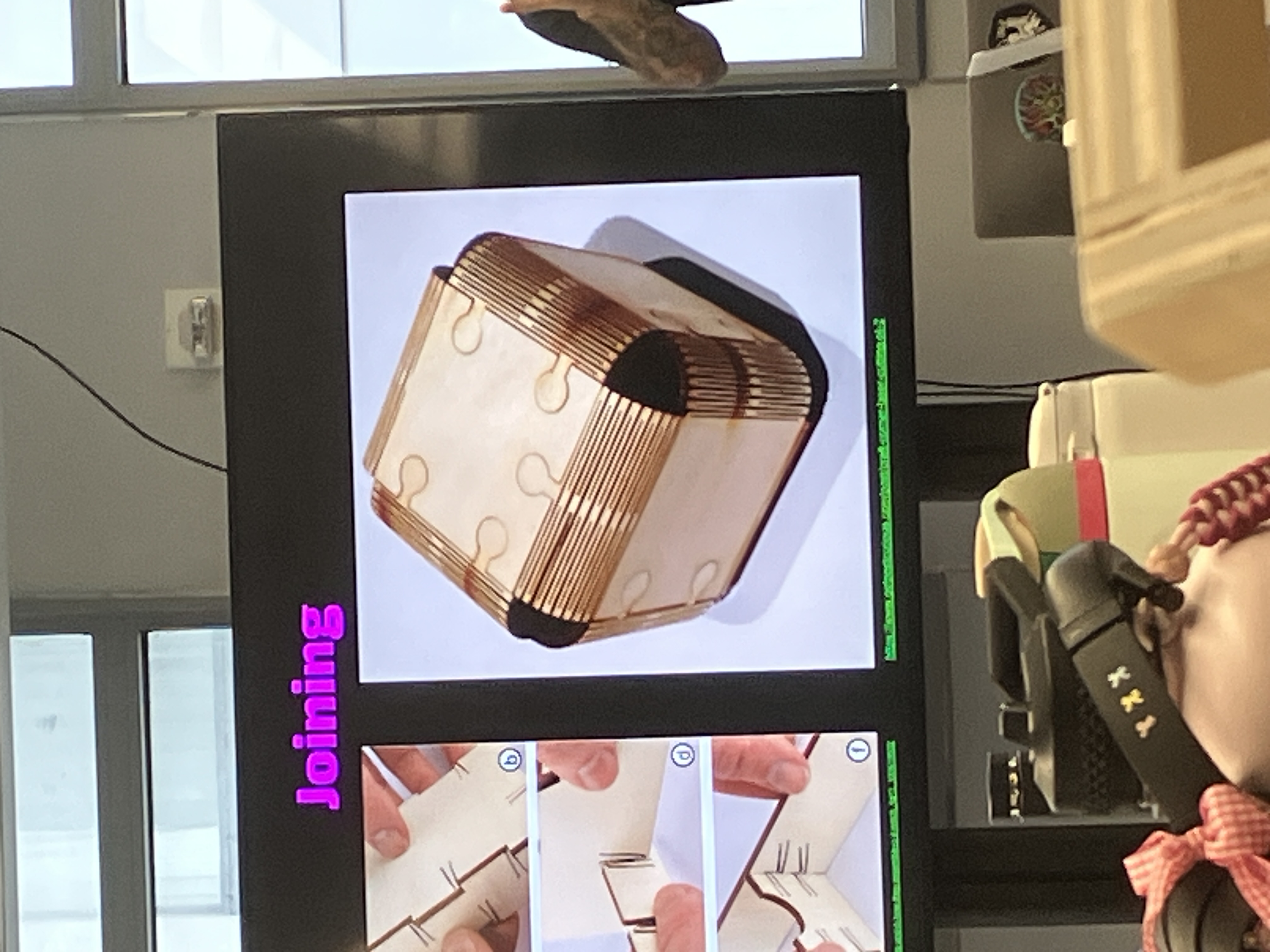

Laser Cut two of the same thing One must be small One must be big at least 6in (160mm) x 6in (160mm) Must use joining Must use two different materials Document on your blog