ask:

Create an enclosure surrounding something.

Look at things like: Small electronics Buttons Batteries Switches The box should be intricate and refined

however, phil & i spoke, about this:

in general, i’m finding it hard to ‘think through’ things. i usually morph whatever idea i started with as & how the material + machine behaves. i don’t think that’s good.

i’m also generally struggling with this course — i was told in my first year that i’m unable to think in three-dimensions. my solution then was to resort to more two-dimensional work, and i don’t want to do that here. please let me know what i should change in my approach.

he then gave me a revised ask:

replicate a volumetric object exactly as is. start with the object, and break it down to the point where they’re flat panels, then build them up.

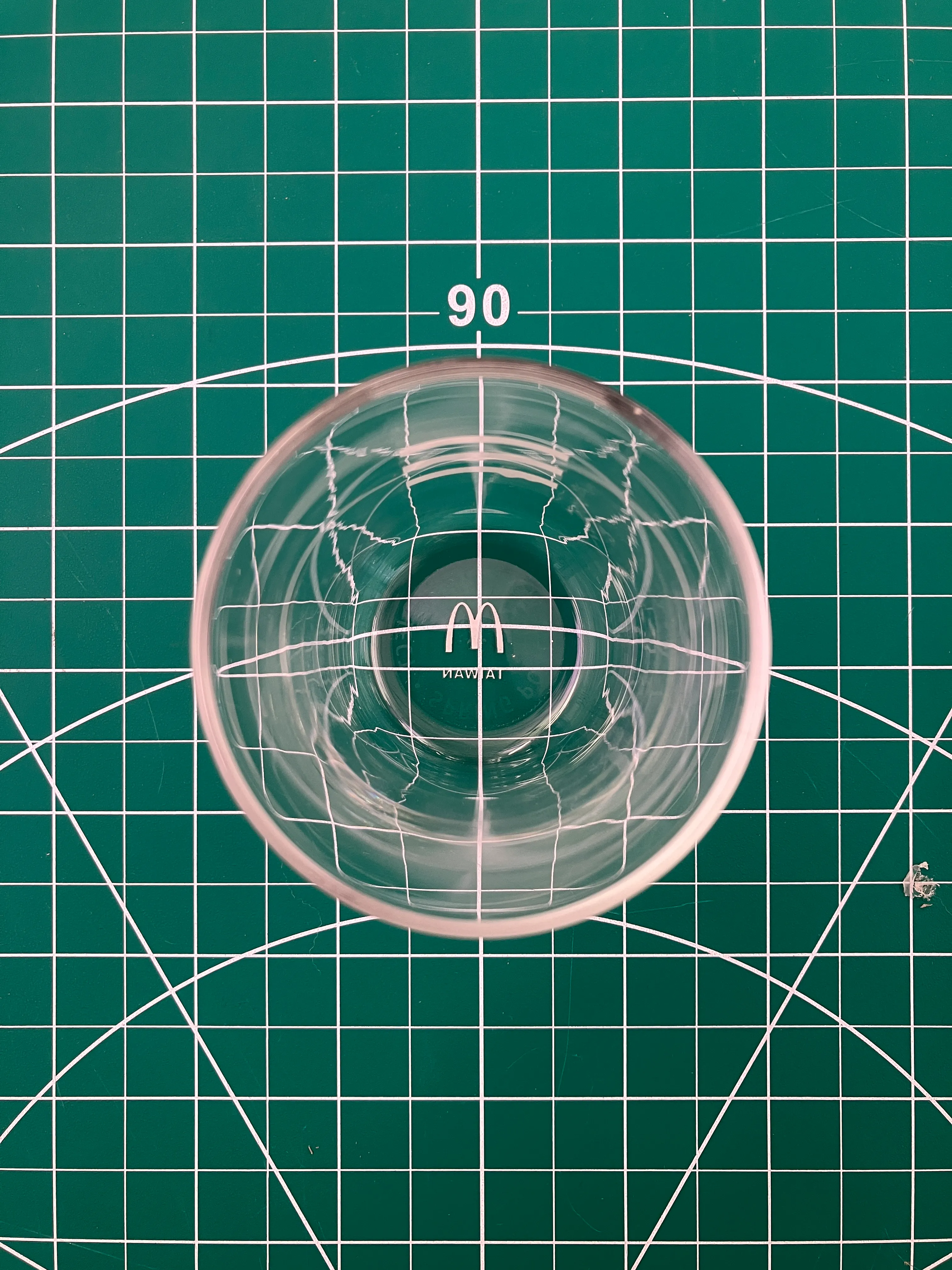

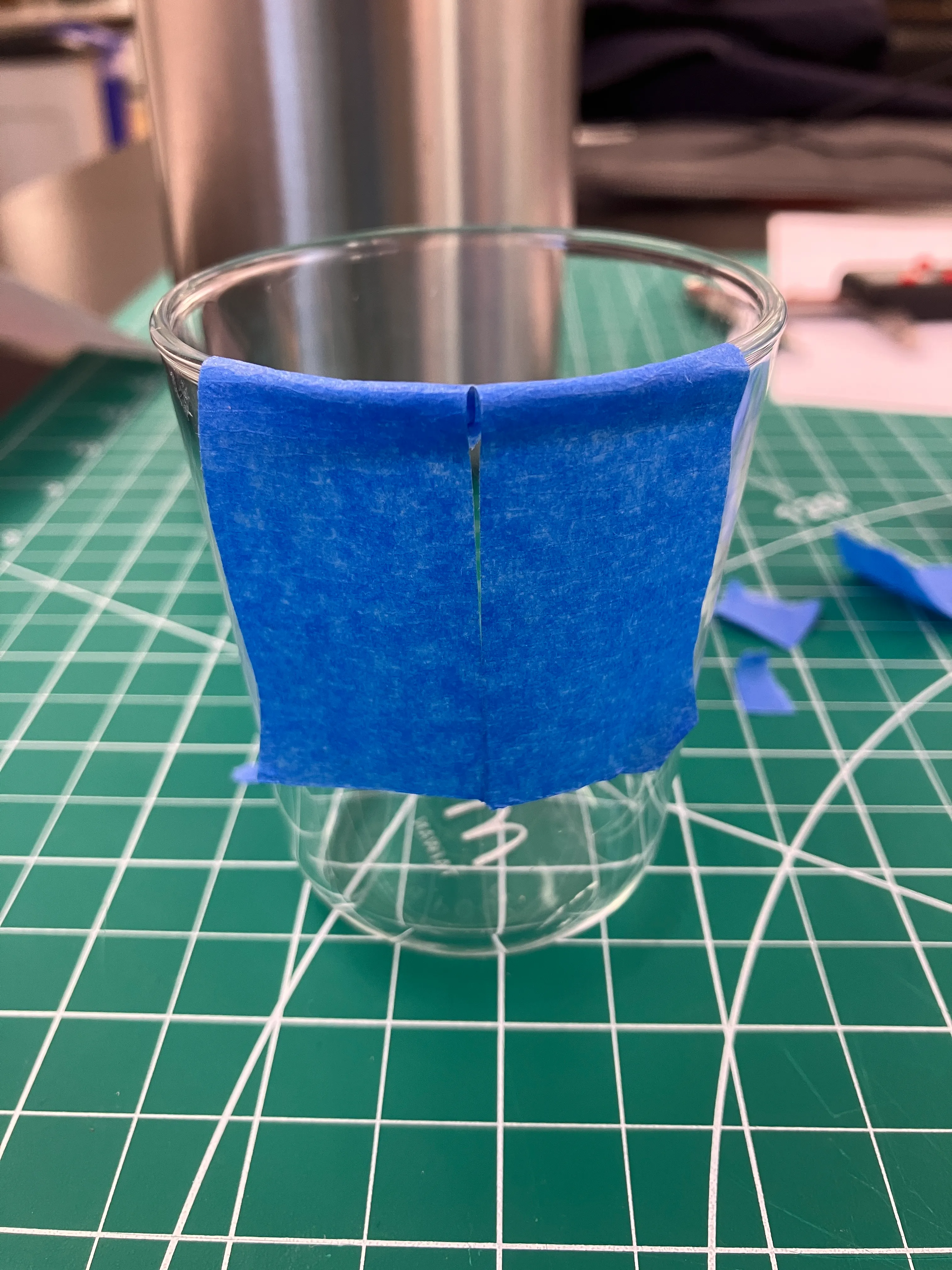

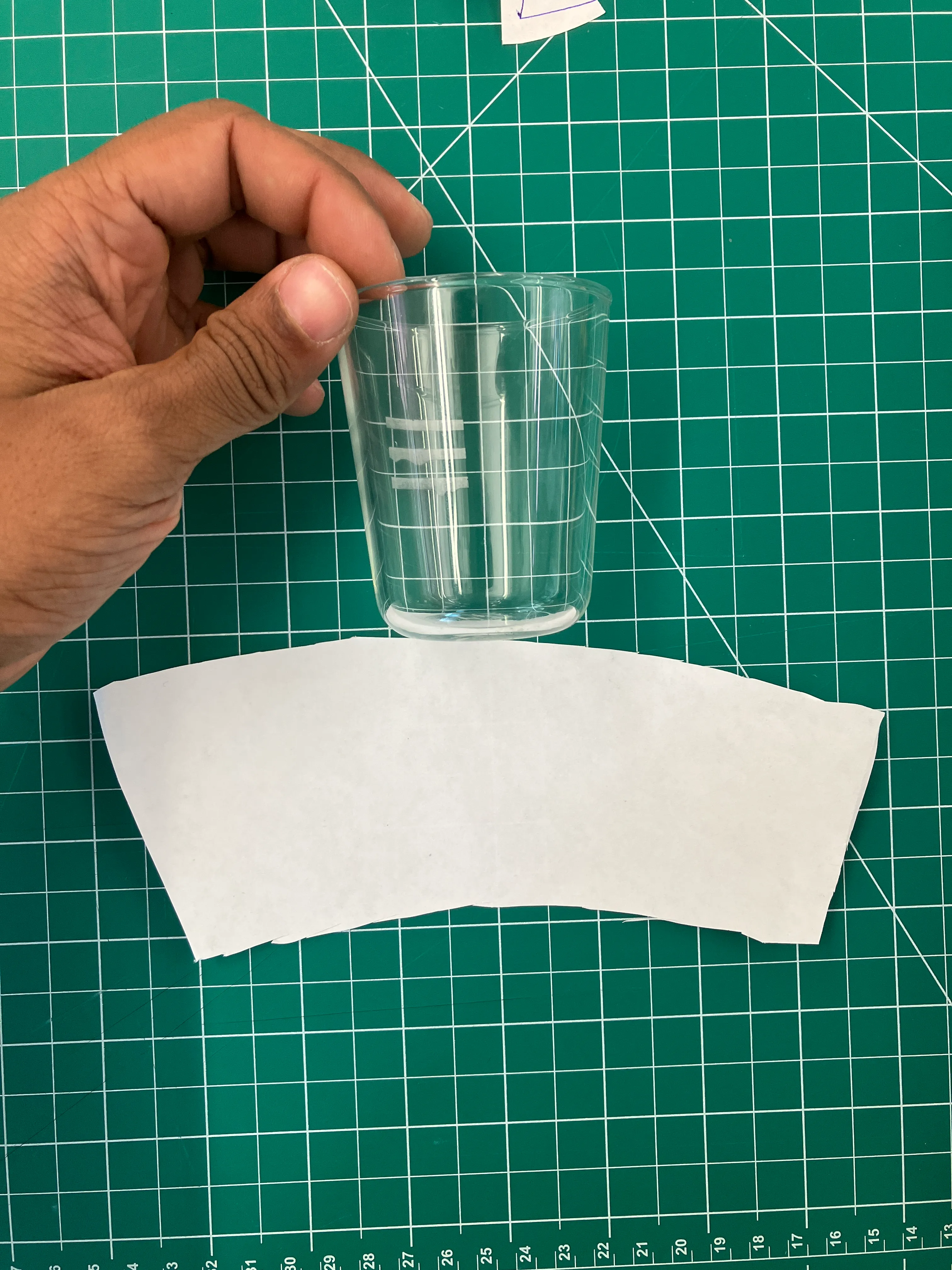

i chose this cup. phil had recommended a conical shape.

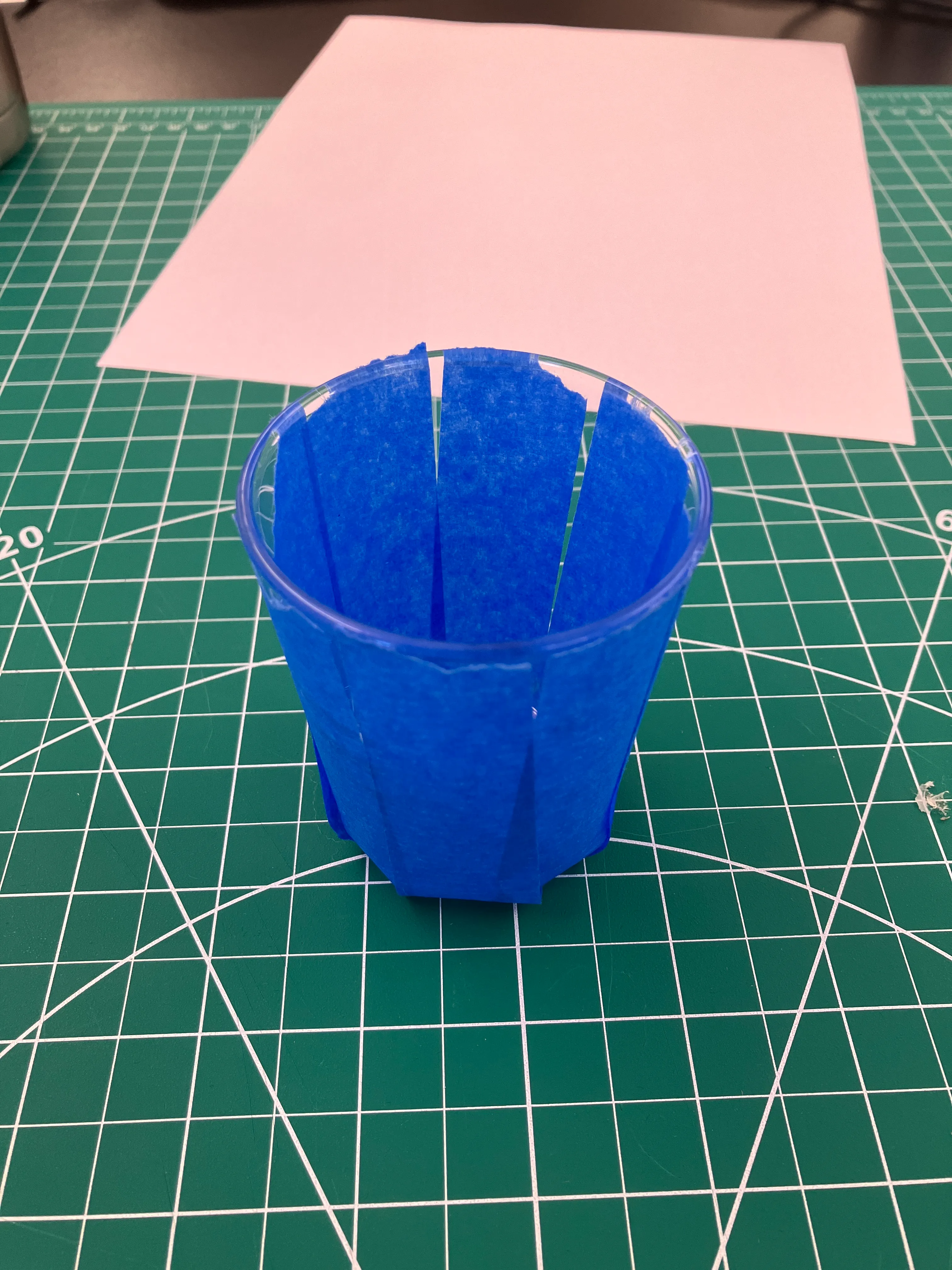

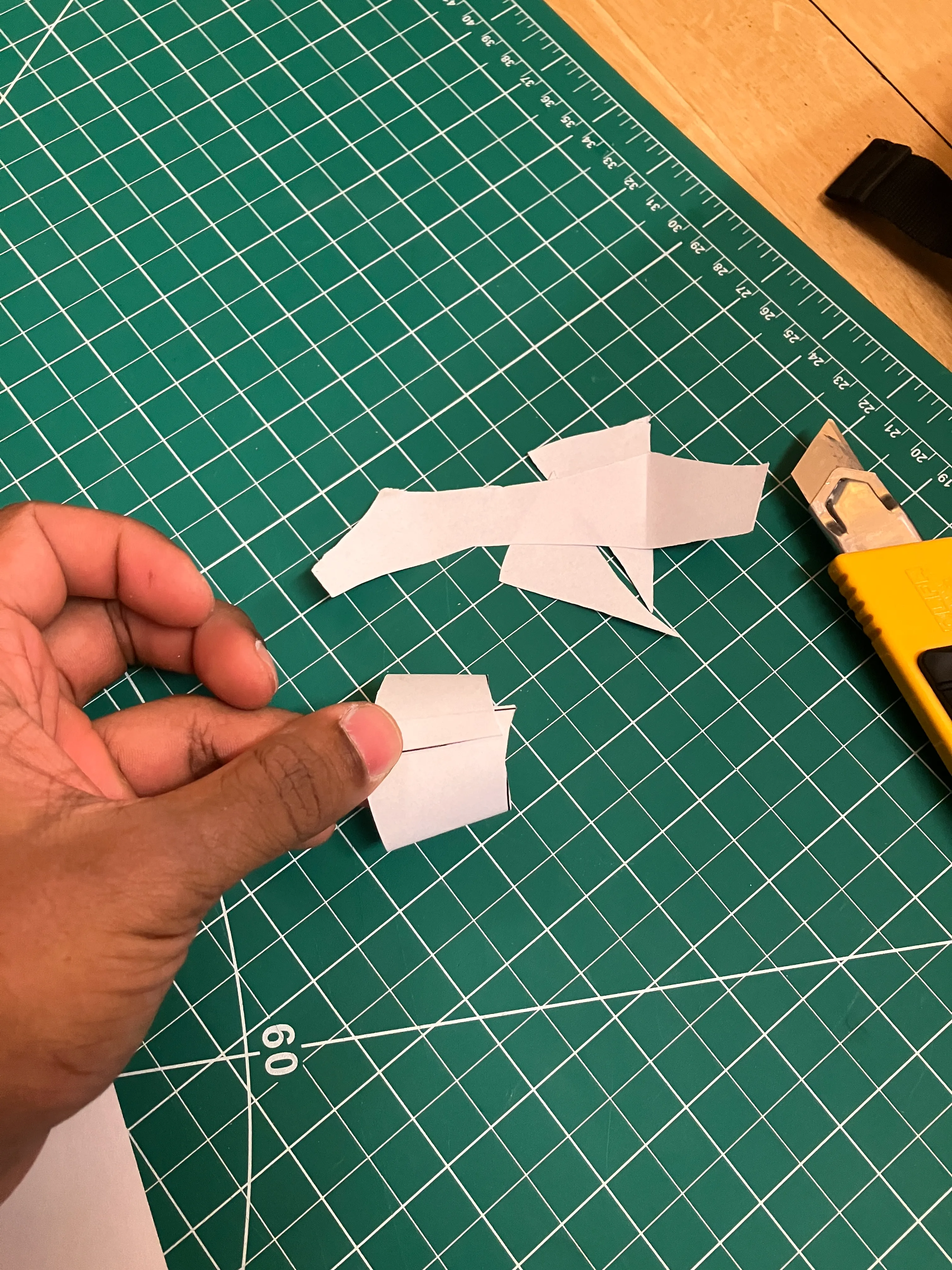

i then taped all surfaces:

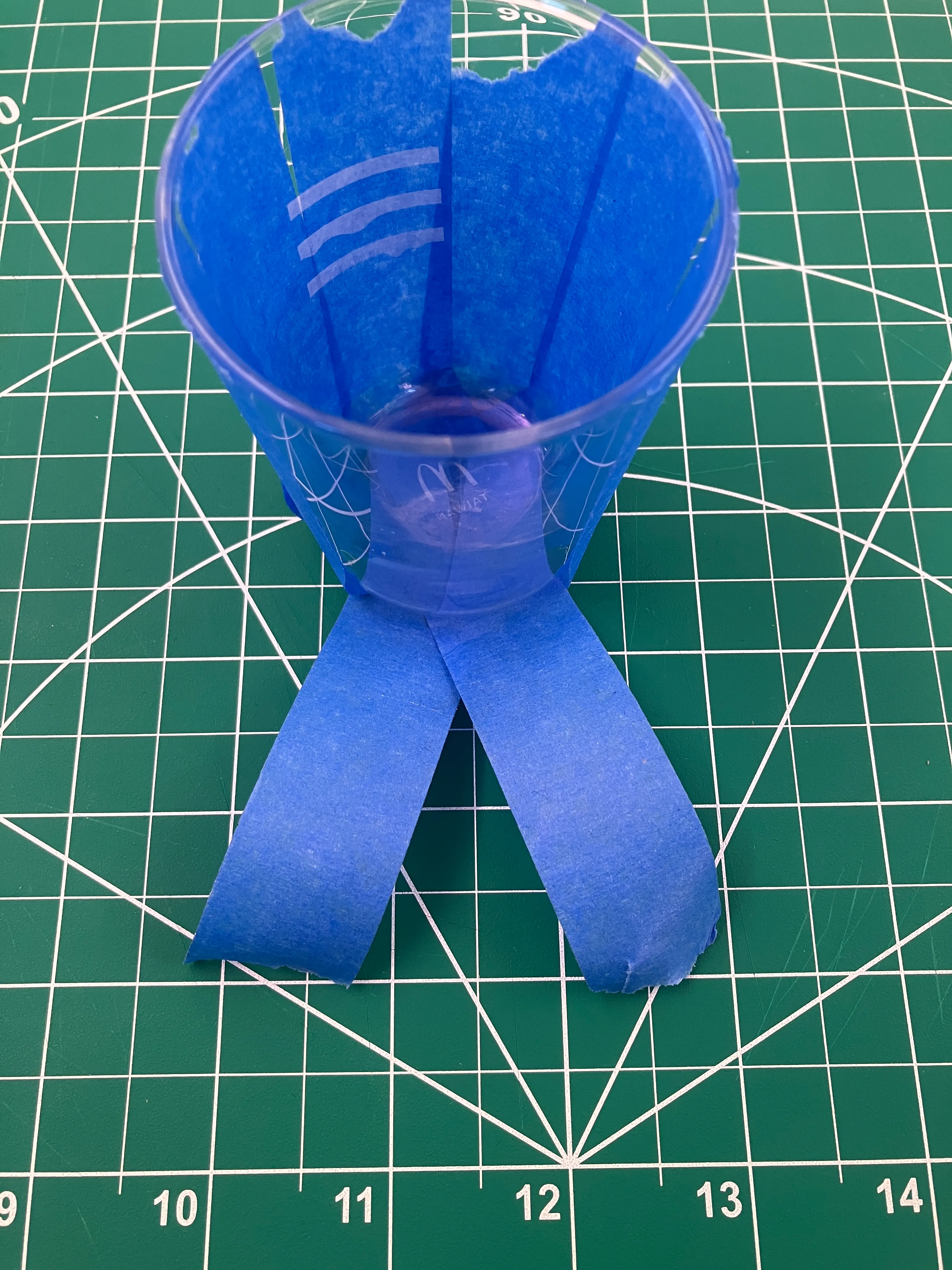

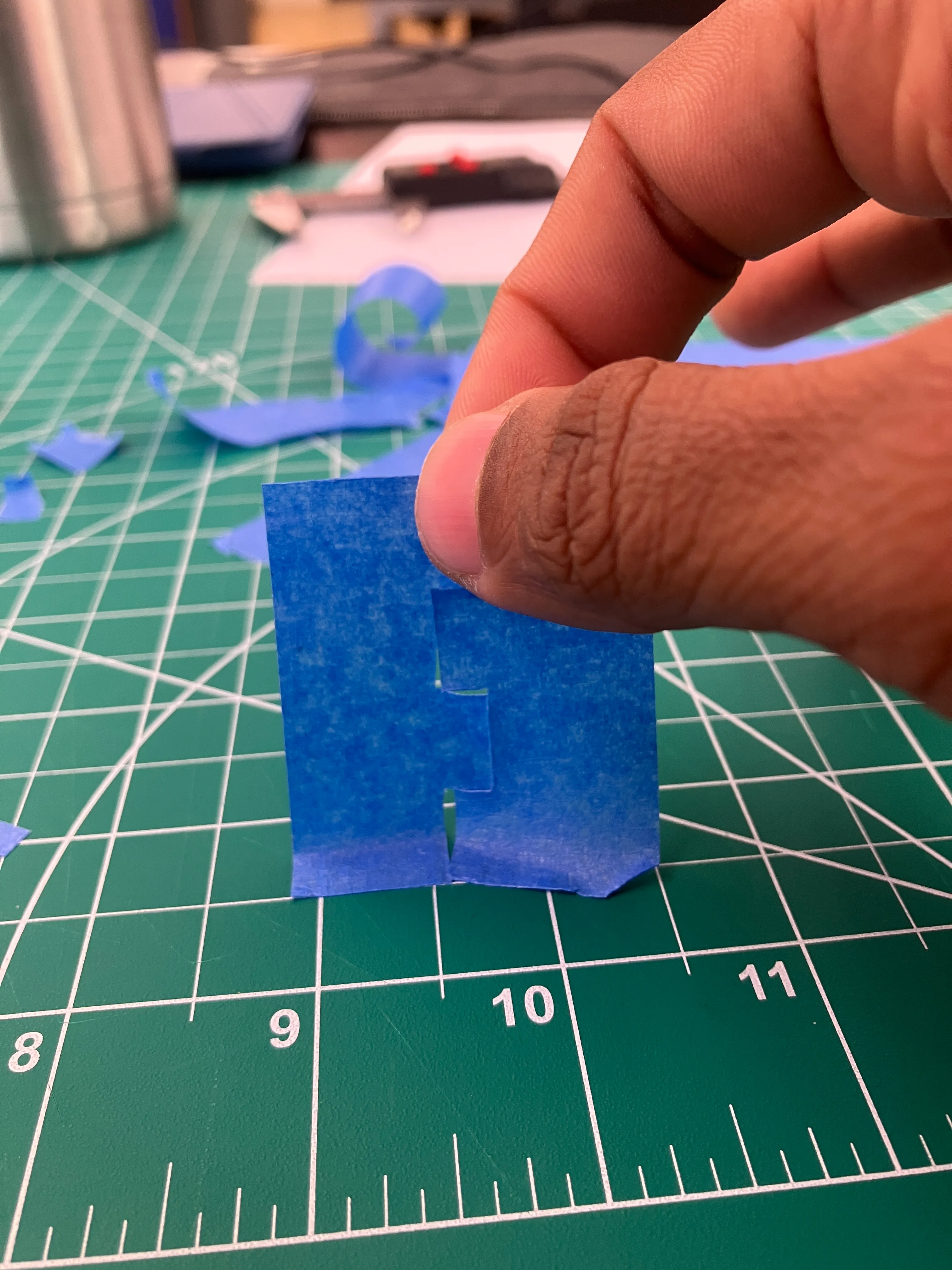

and opened them up.

realised that because the top is bigger, they actually don’t meet edge-to-edge when laid flat out. i wonder what the math is.

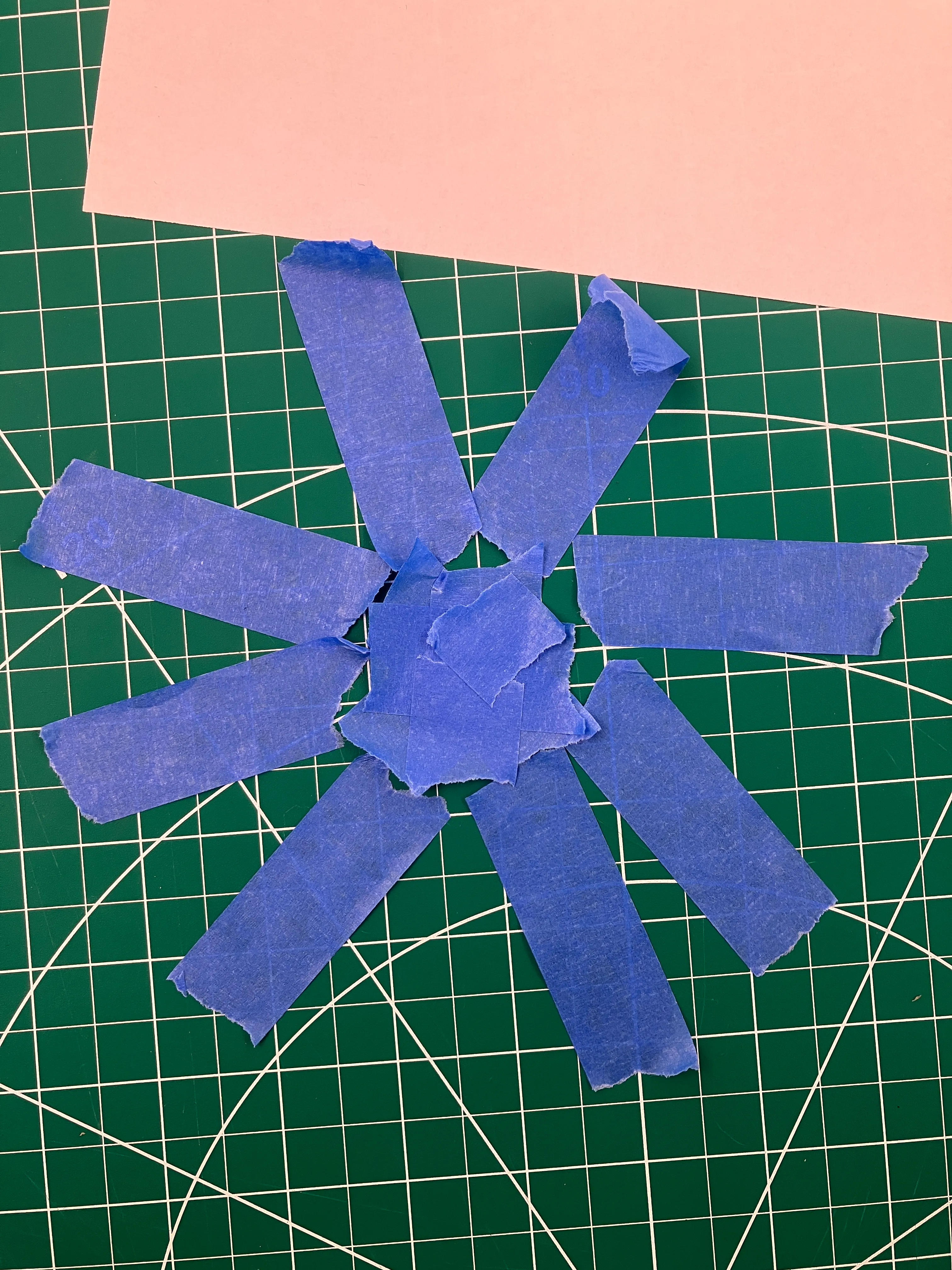

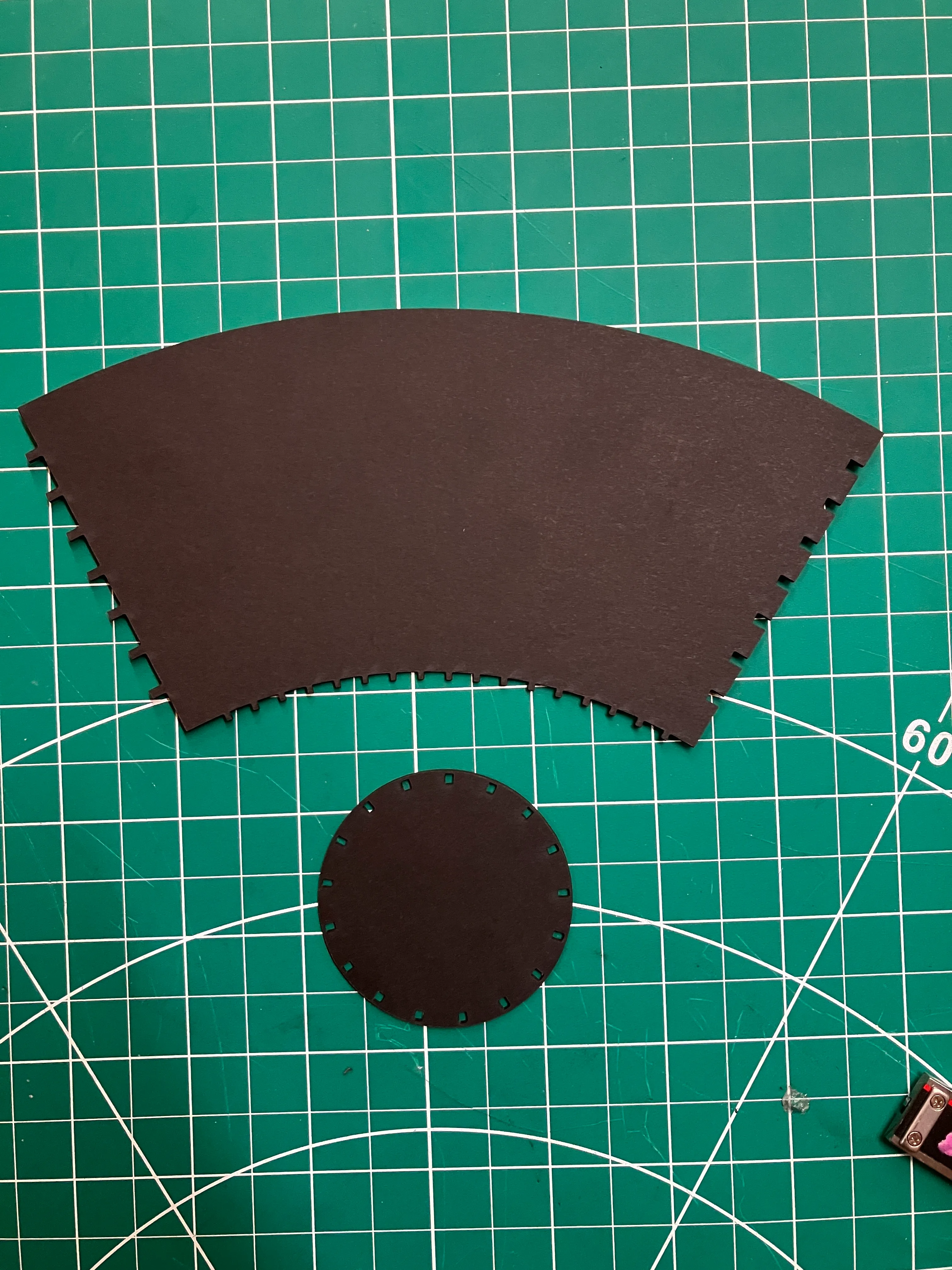

the whole shape when opened looks like so:

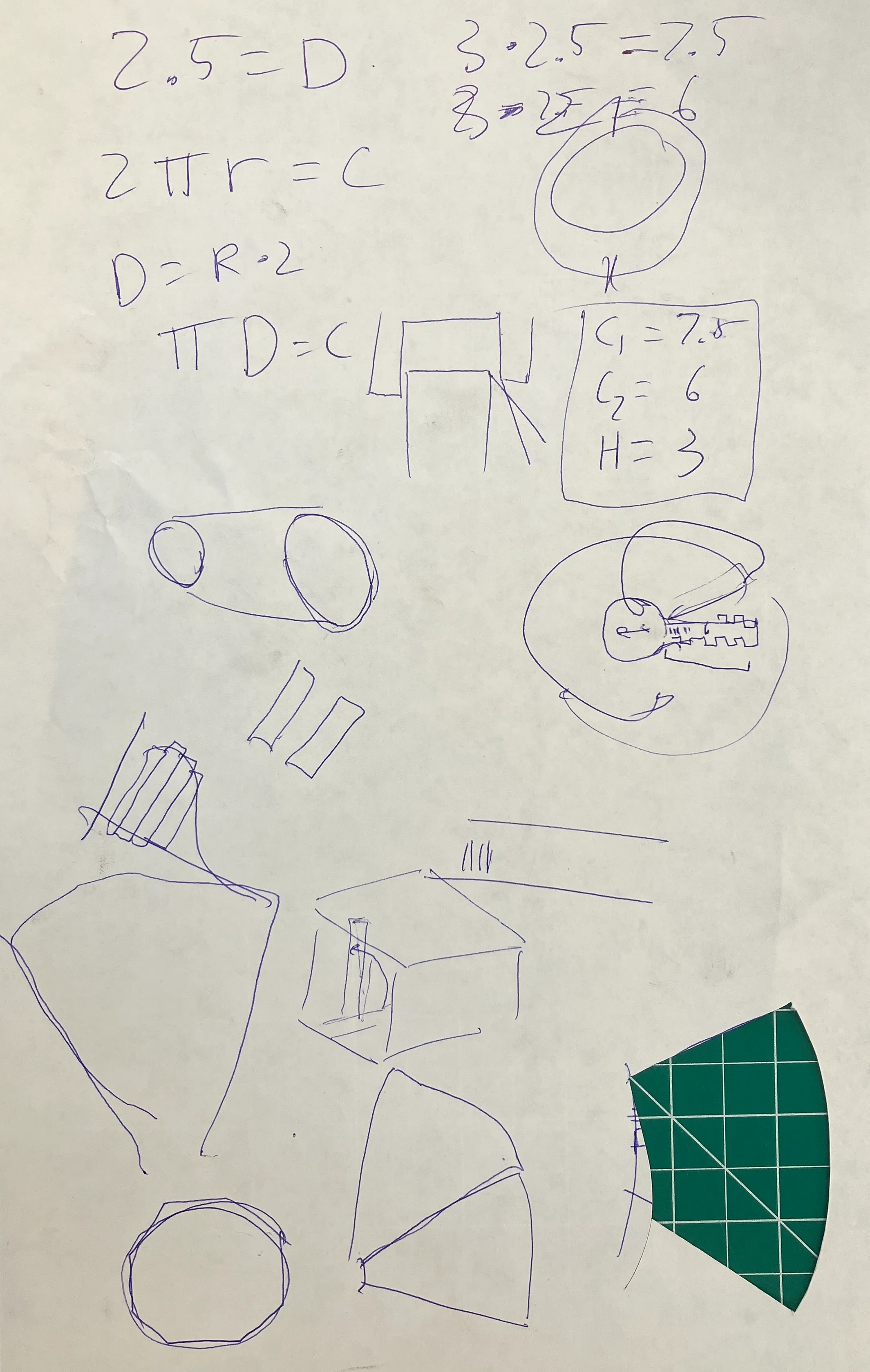

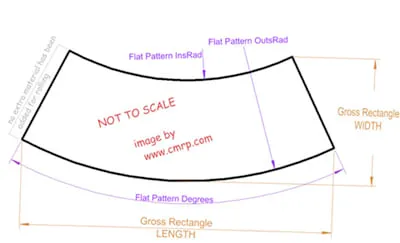

figured this out:

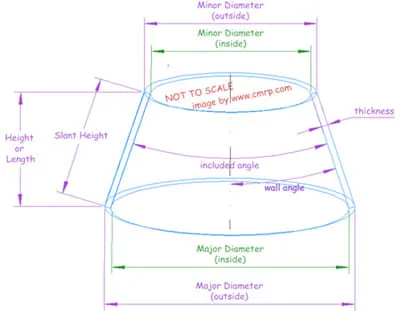

to calculate the diameter of a larger circle in a circular cone, you can use the formula d=2r, where r is the radius of the base of the cone.

realised that when two parallel surfaces of a curved surface lie flat, they’ll have some distance between them. i can see this visually, although i still don’t understand how.

maybe i can’t think volumetrically.

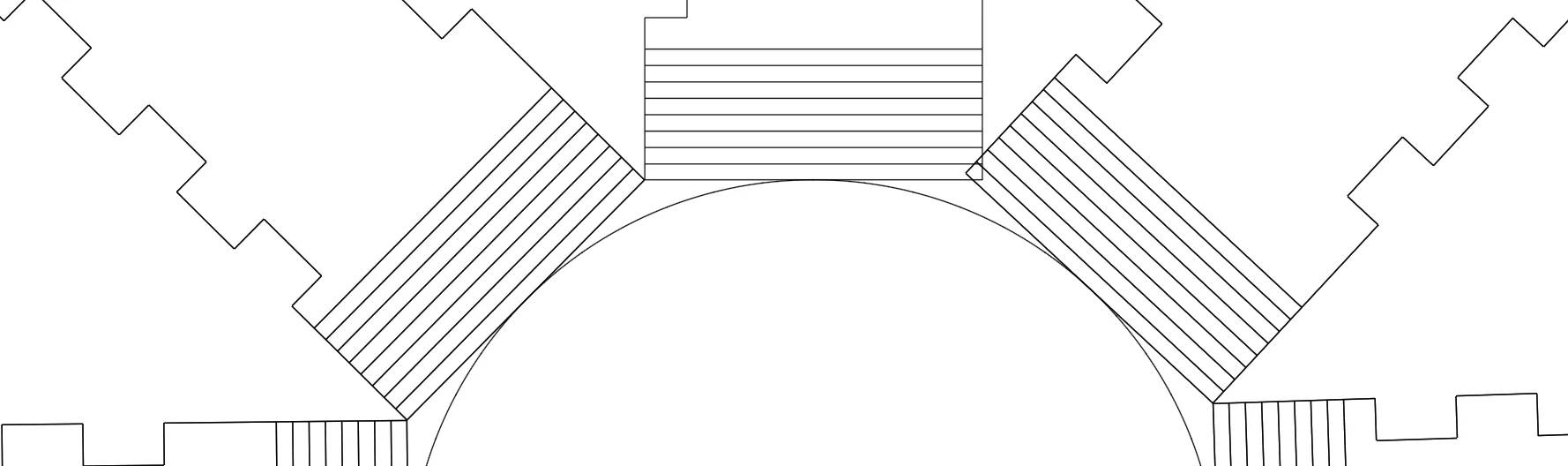

next, i tried to figure out the joints.

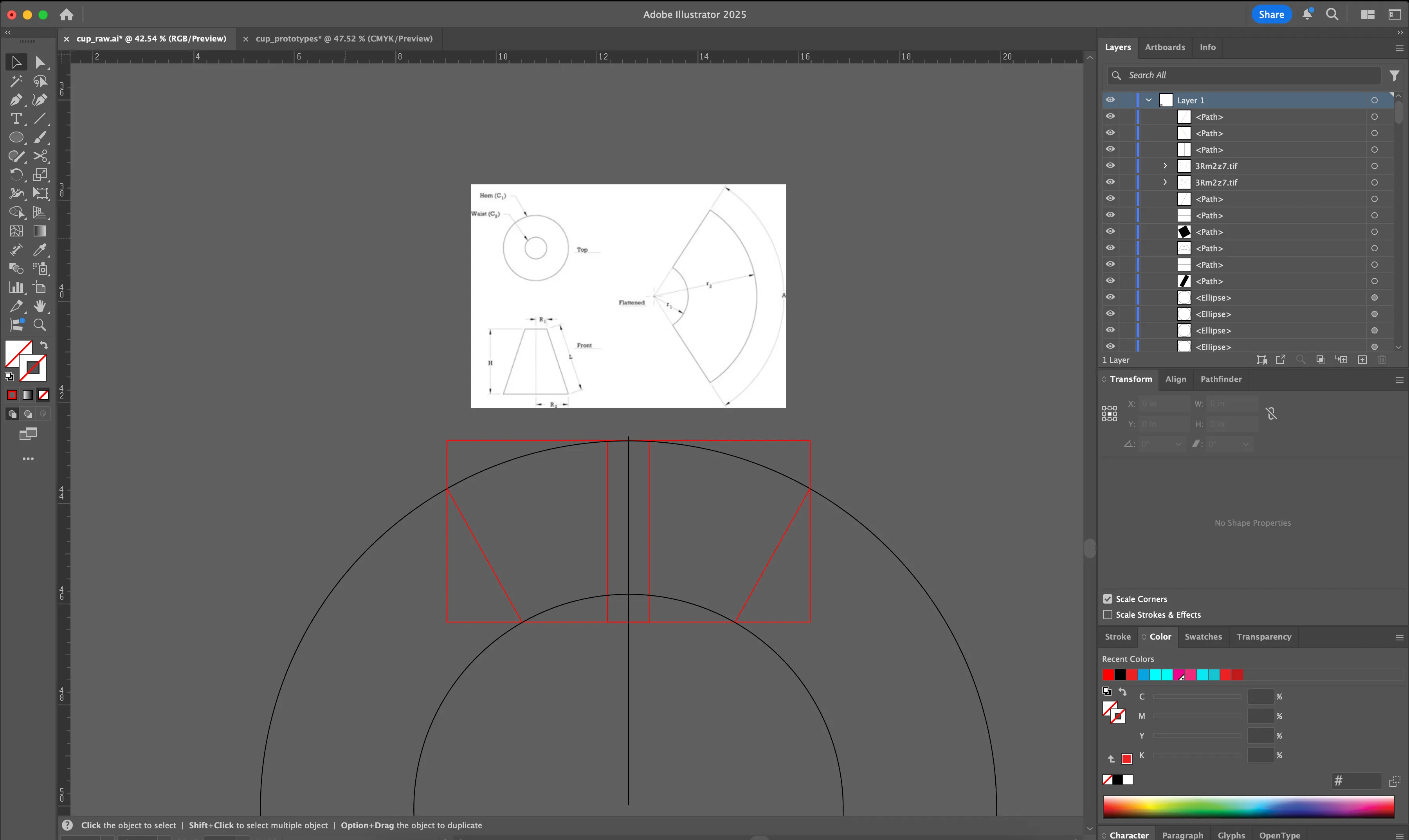

then, i carefully sketched the components out.

realised i did the math wrong for each panel.

width has to be:

where c = circumference.

height has to be

where r is the radius of the base.

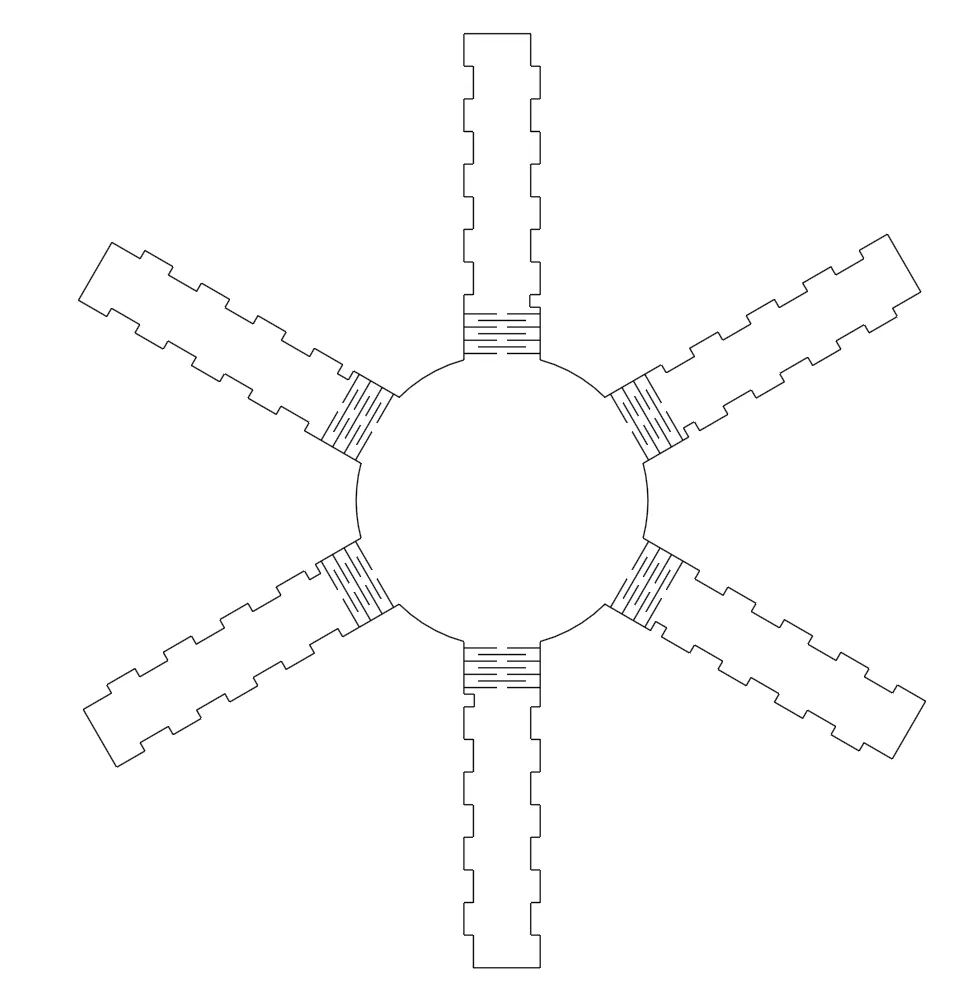

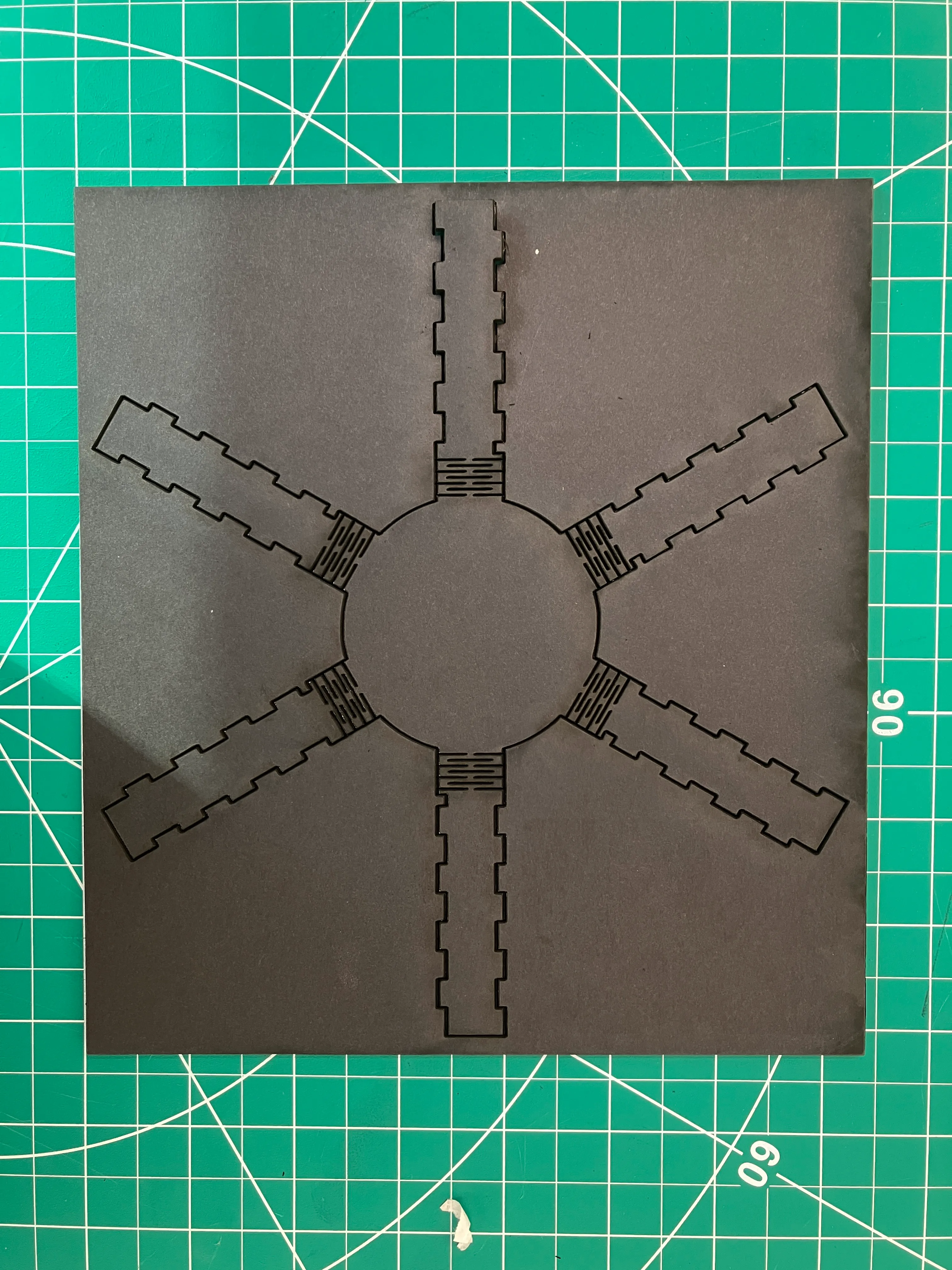

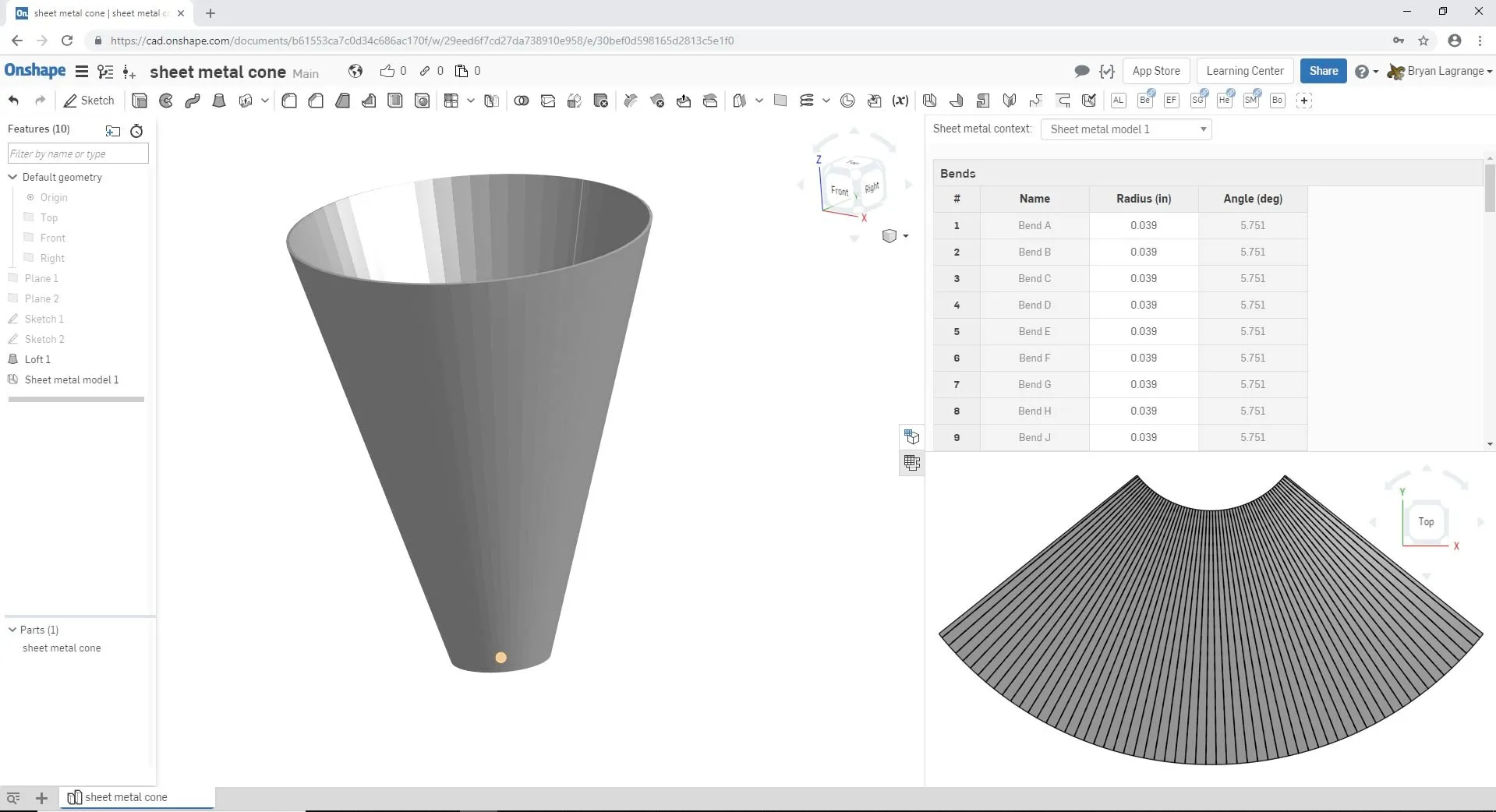

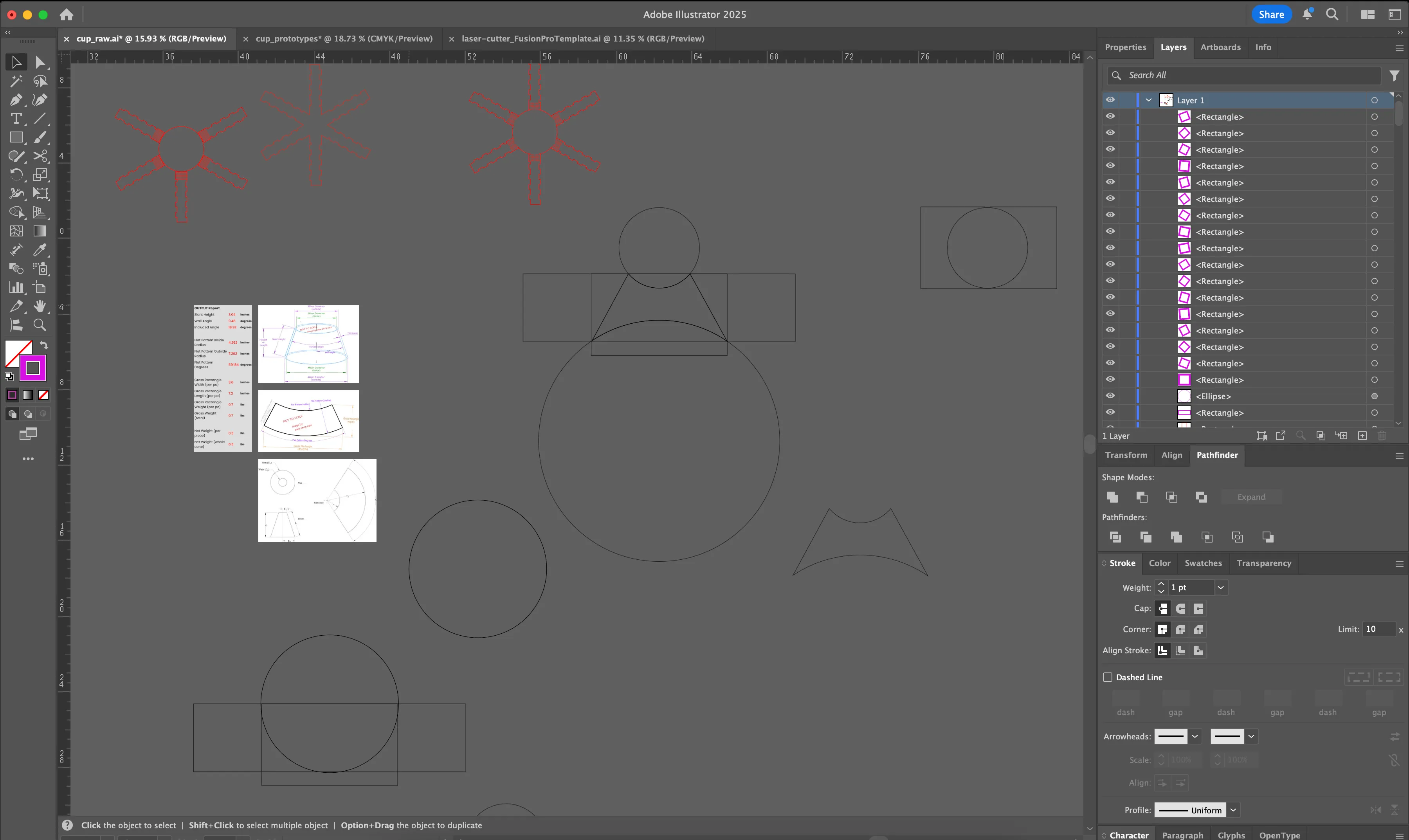

i then made the compounded-shape.

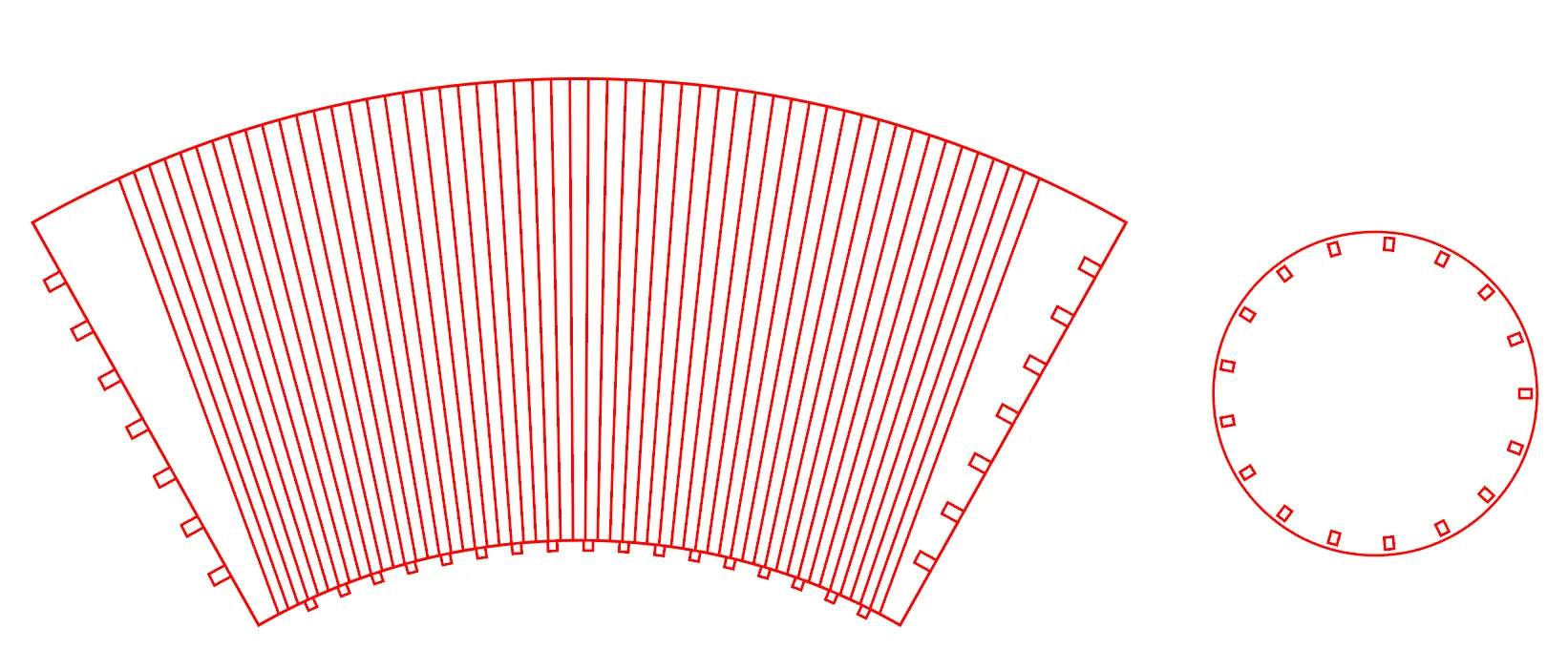

laser cut it.

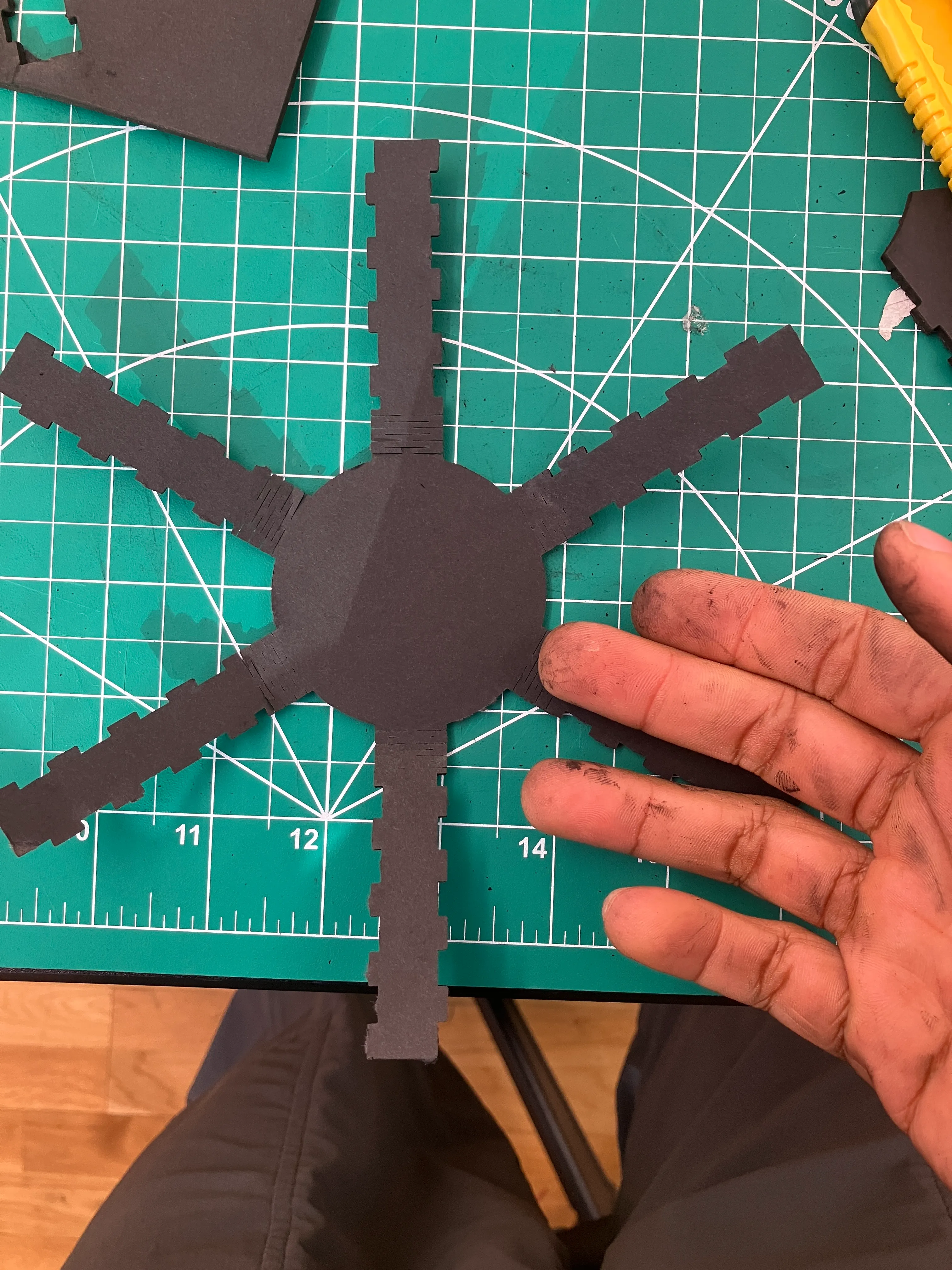

and realised that i used the wrong circle as the base.

then i used the smaller circle and i forgot the kerf lines, and it didn’t bend. even if i forced it, the ends didn’t meet.

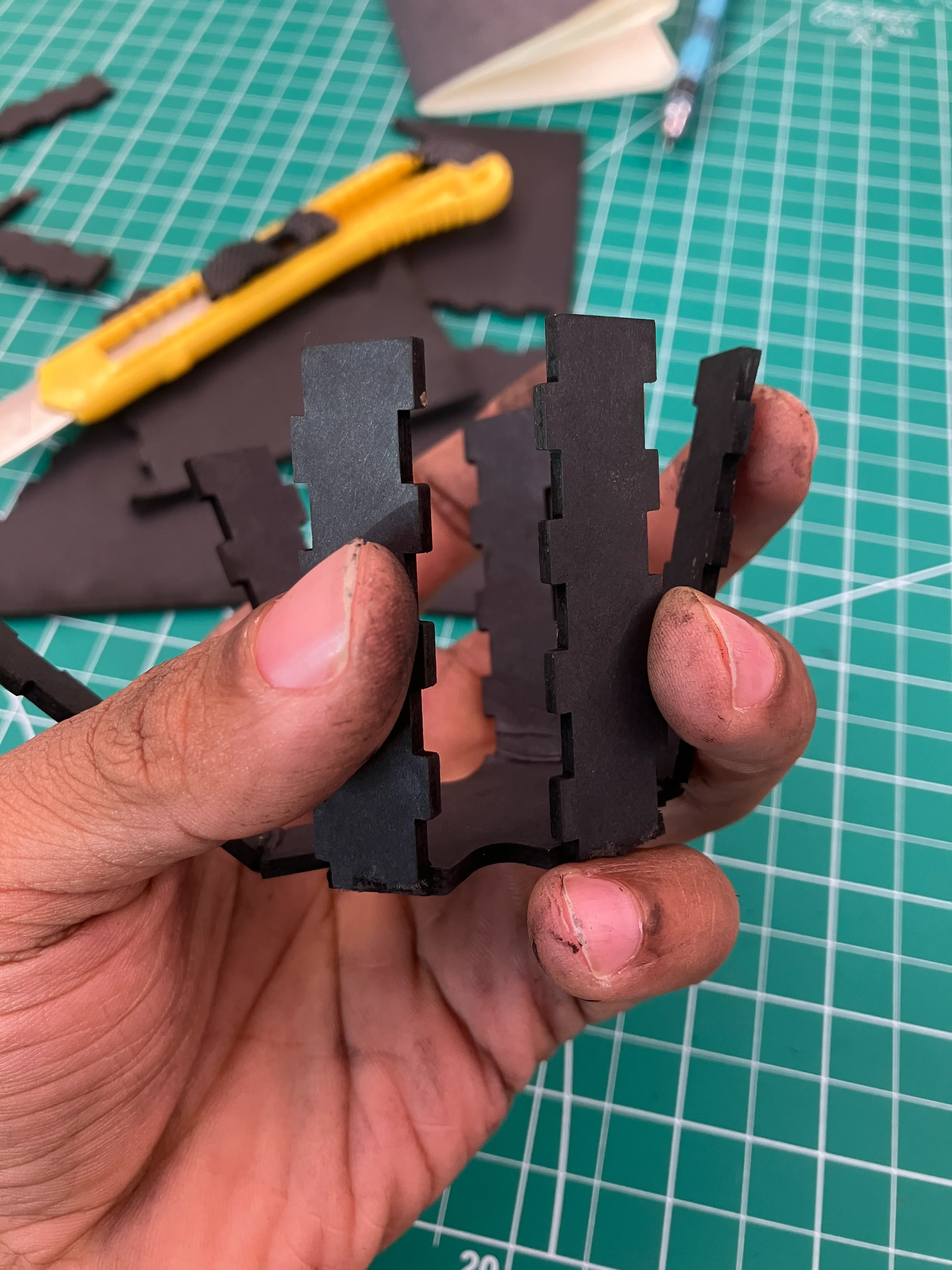

then i scaled everything down, to have more joints. then it broke.

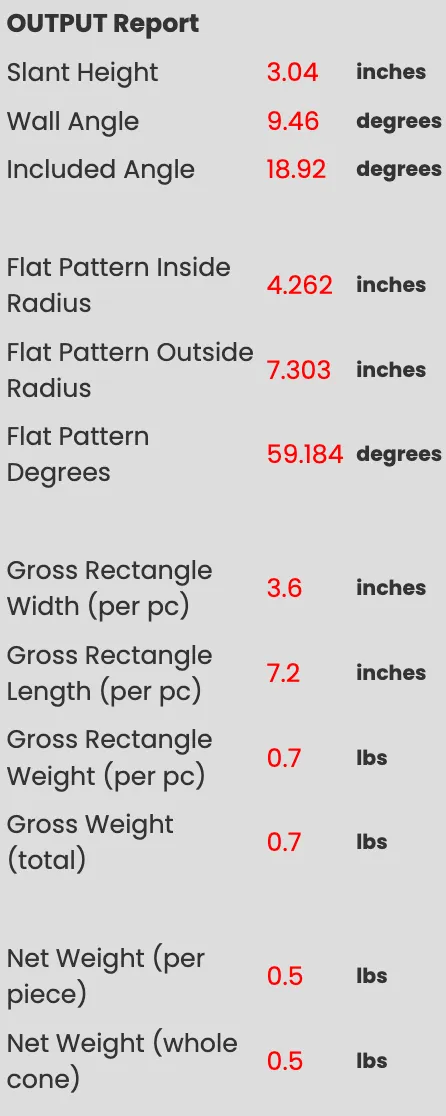

then i saw this:

tried one more approach. failed.

cody helped me see why my earlier prototypes failed.

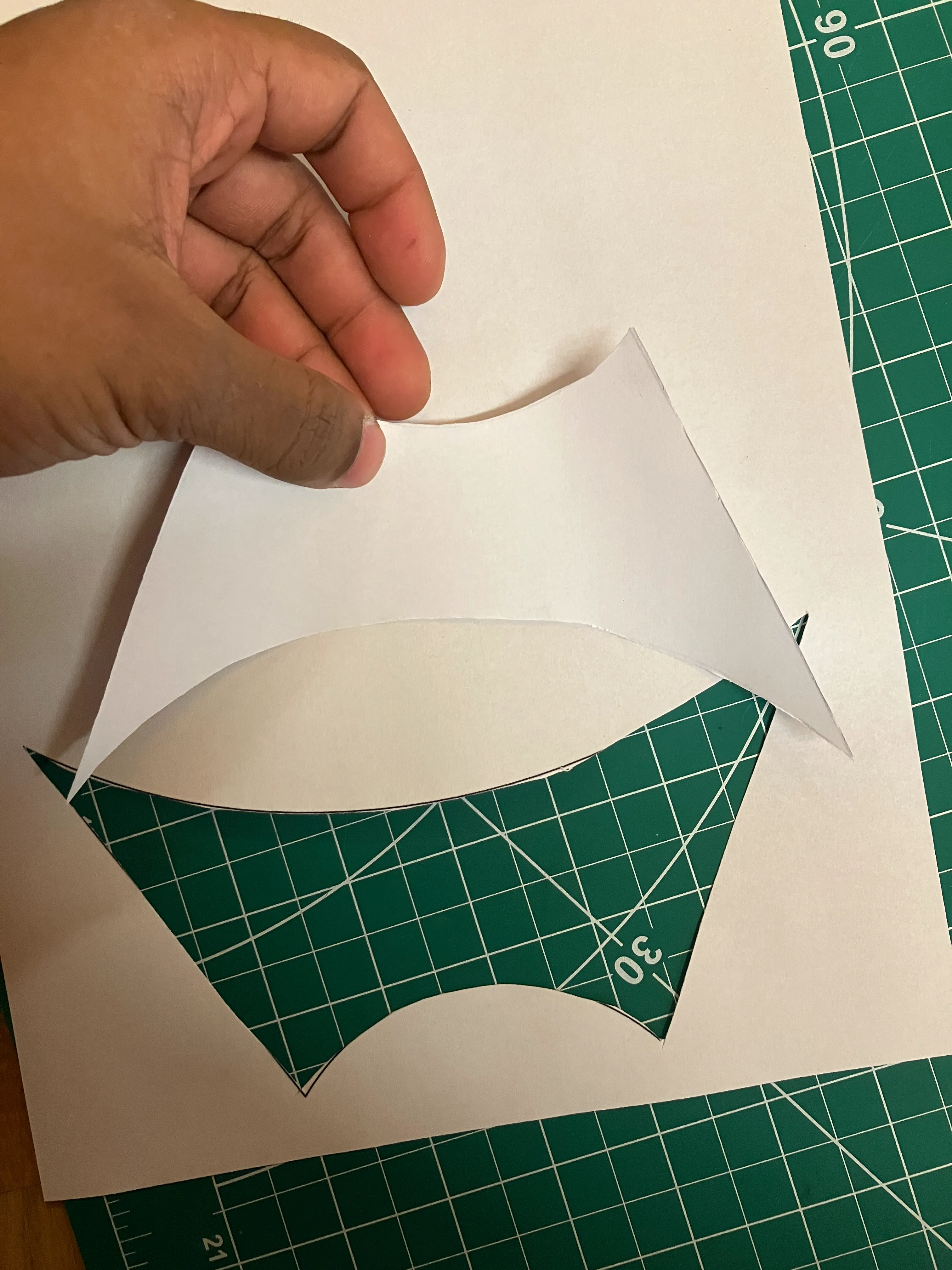

i then got a piece of paper (as per his suggestion), wrapped it around the container and cut it out with a scissor. that made me see the general shape i should’ve gotten.

i then found this:

i then tried — really tried — to get the shape right.

printed it out on paper to test:

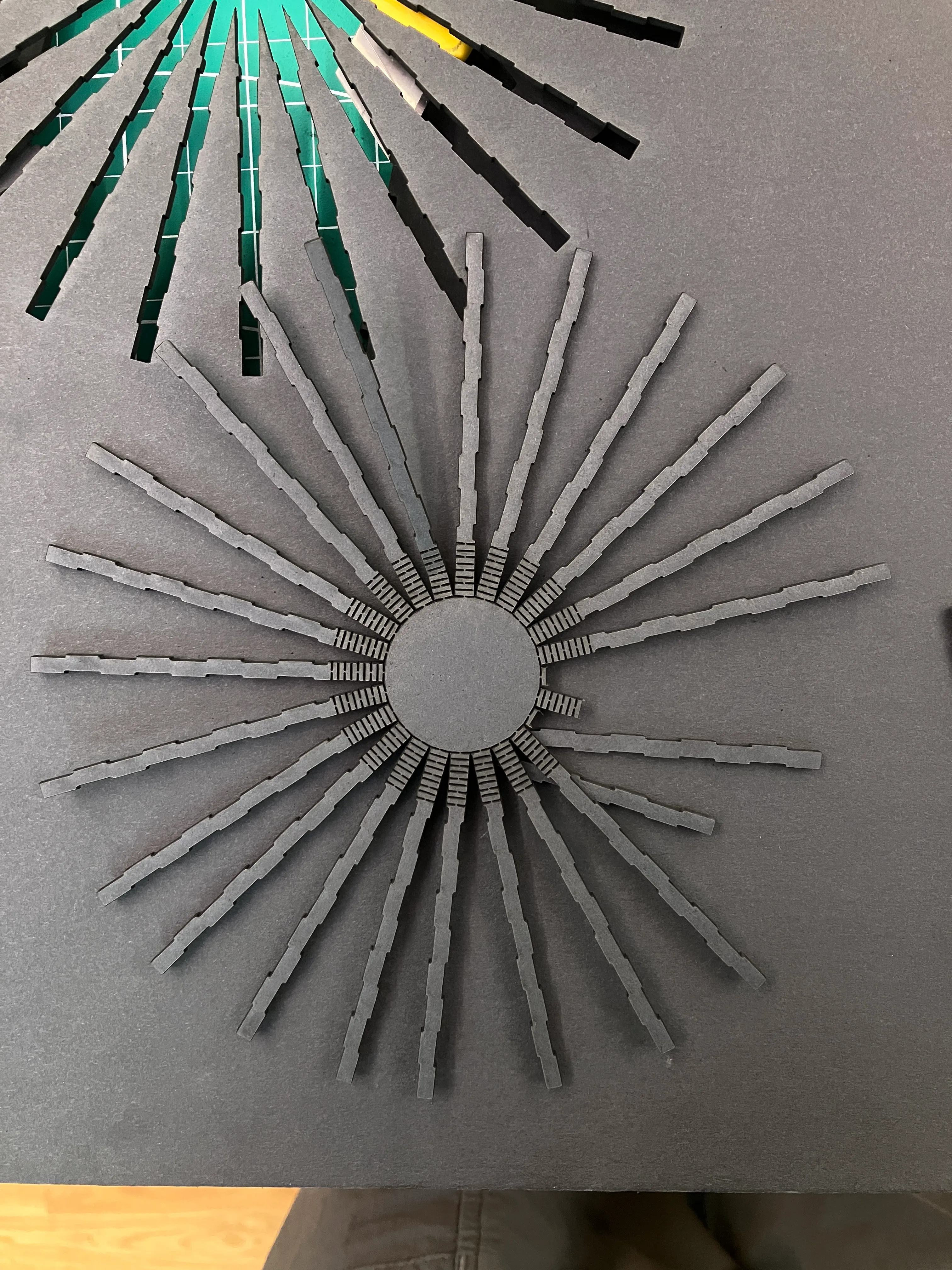

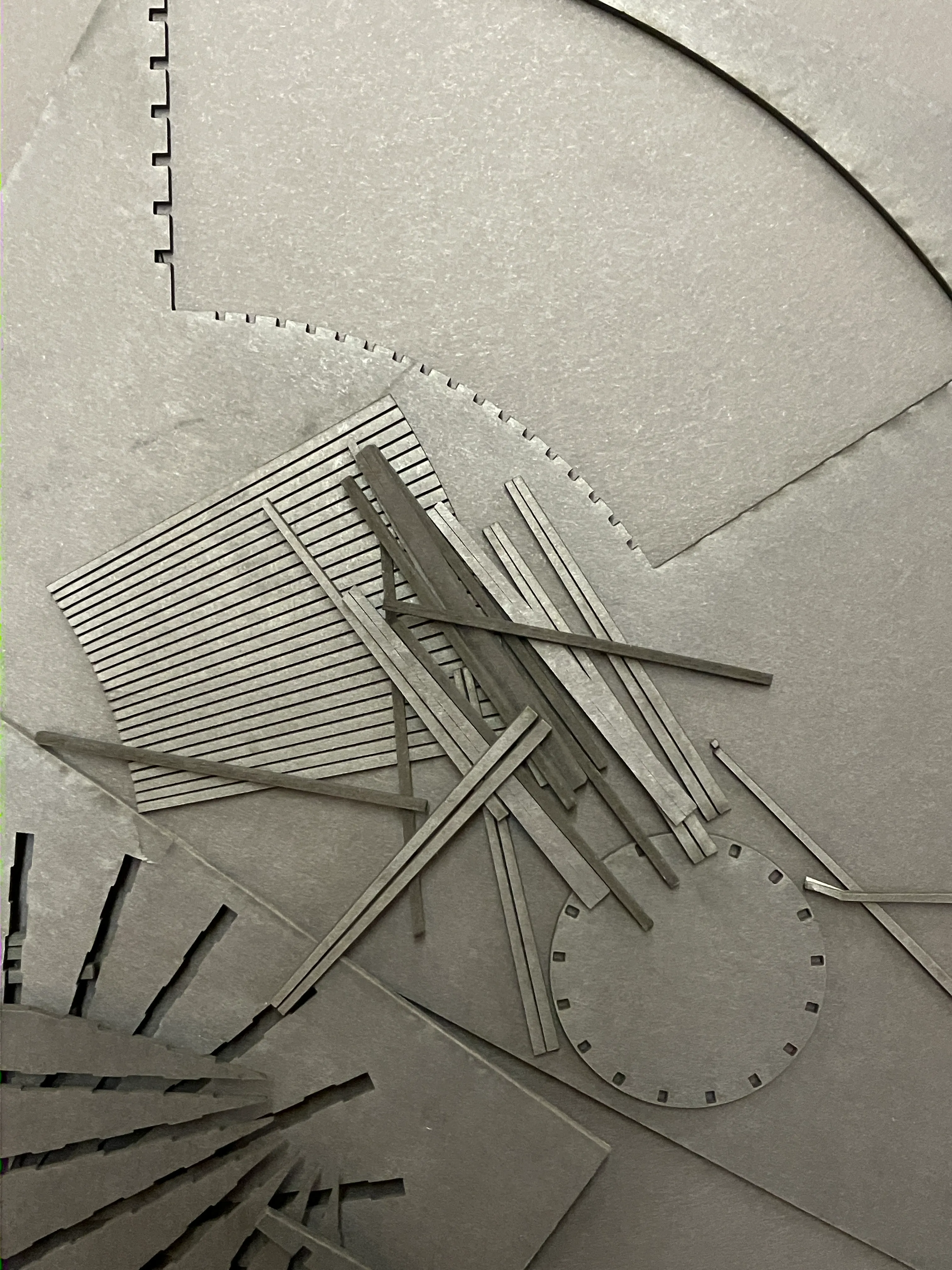

laser-printed this:

it was a mess.

everything broke. i hate it. i hate this.

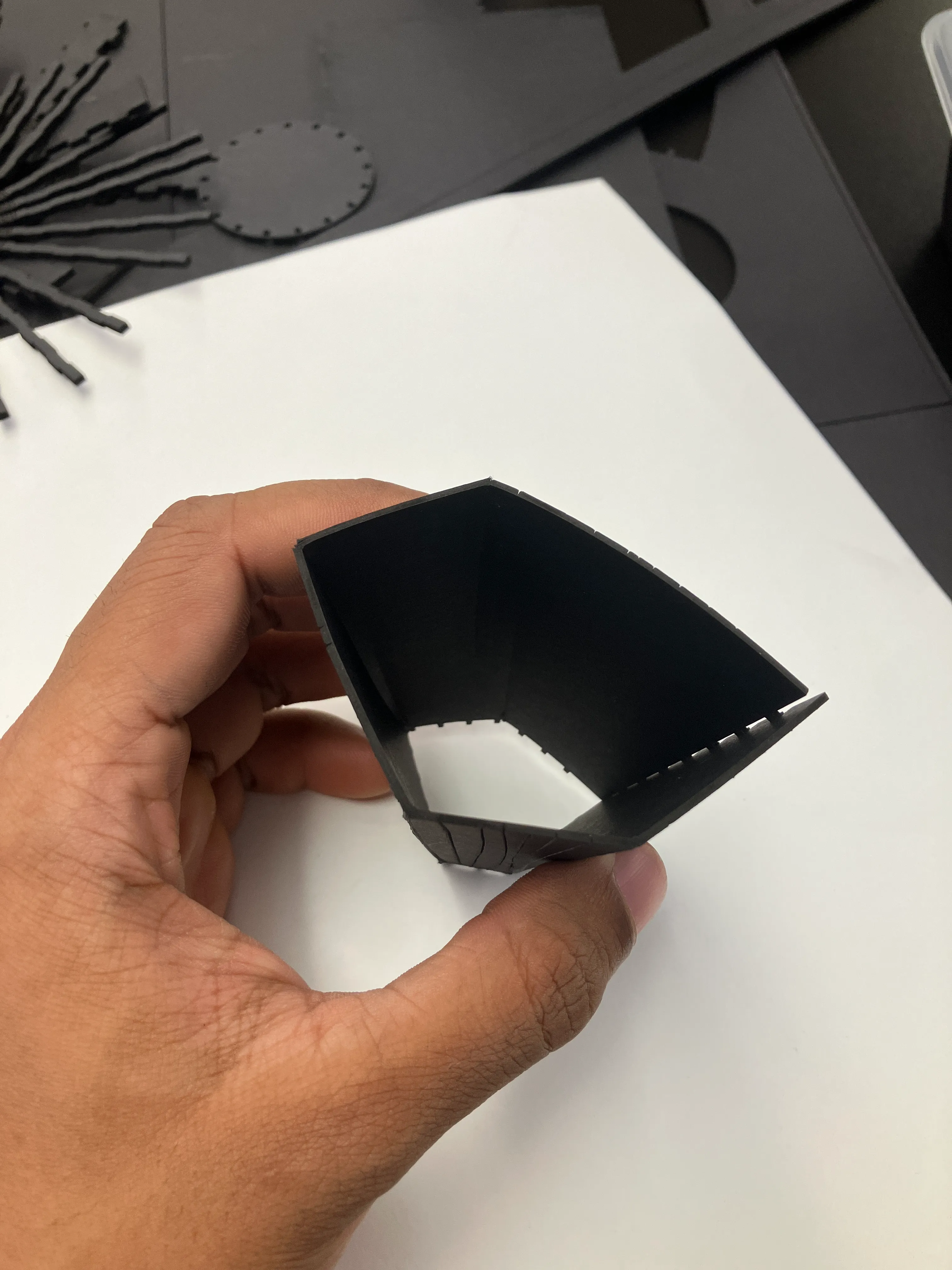

i laser-cut this on a thinner material.

did not include the kerf-lines, because that fucked things up last time. but then the material wouldn’t bend. i decided to make the kerf-lines by myself (half-cuts with a cutter) to make it bend.

it’s 2140. i’ve spent more than 10 hours on this. i hate this.

this is what i was left with.

reflect:

it was good to fail — i haven’t done that in a while. i now know that i’m not great at fabrication, and working in the course with that realisation eases the general pressure (see the pressure to do big things) i have.